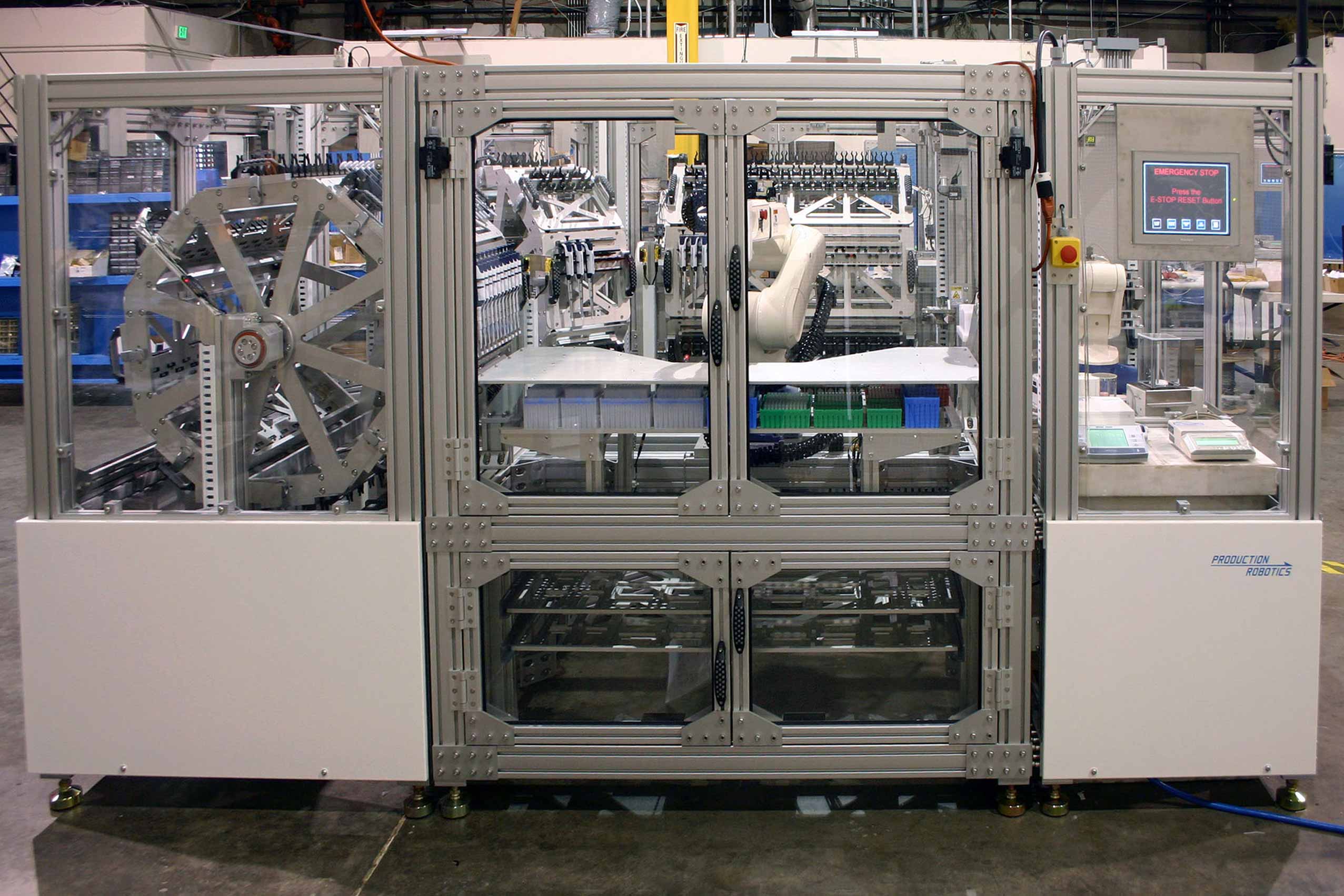

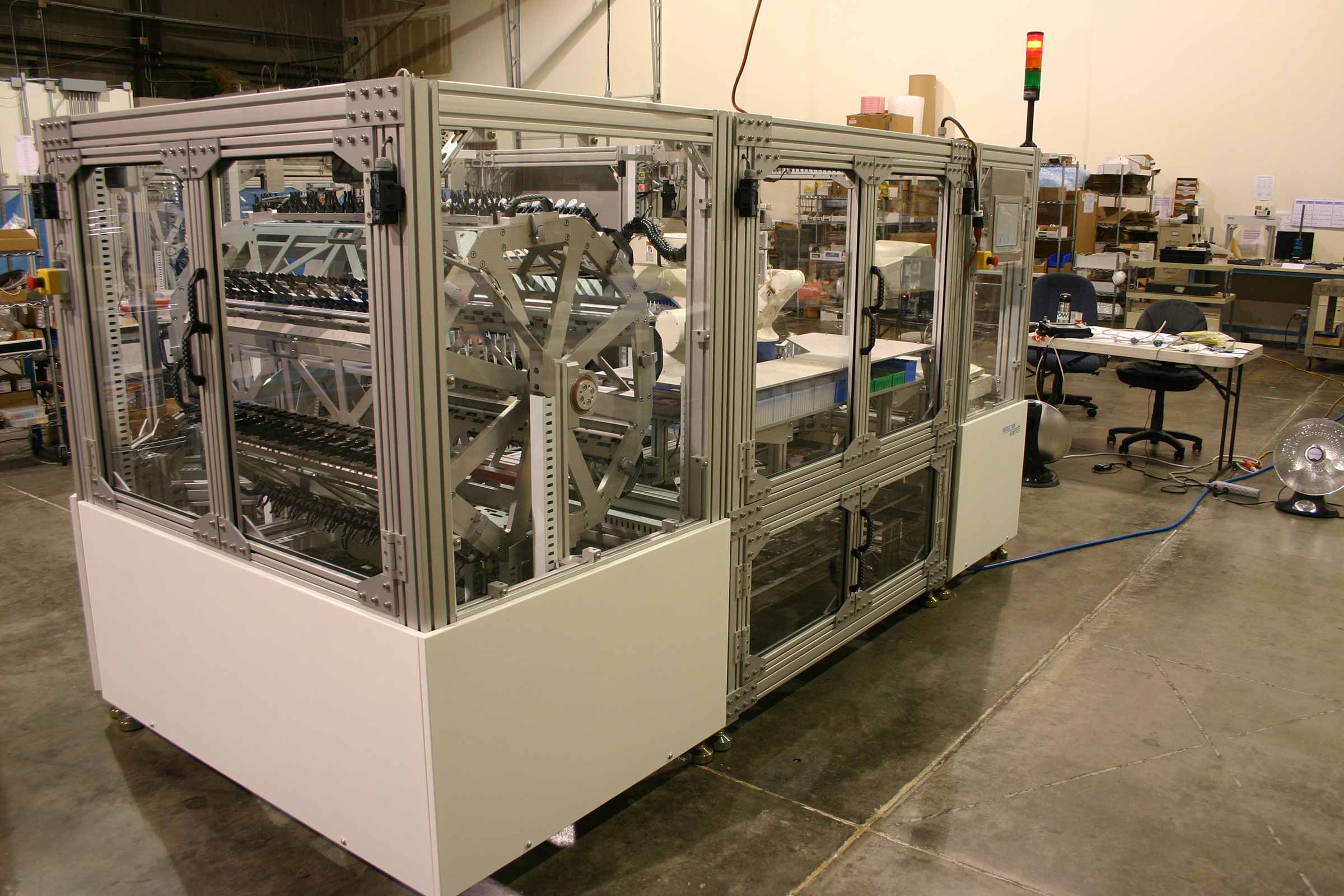

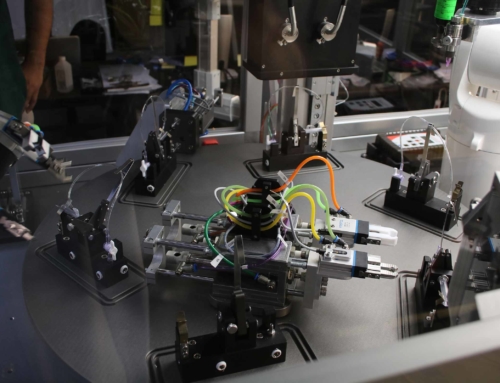

For a manufacturer of precision pipettes used in the medical, chemical and biotechnology industries, Production Robotics developed this automated test system for manually operated pipettes in production.

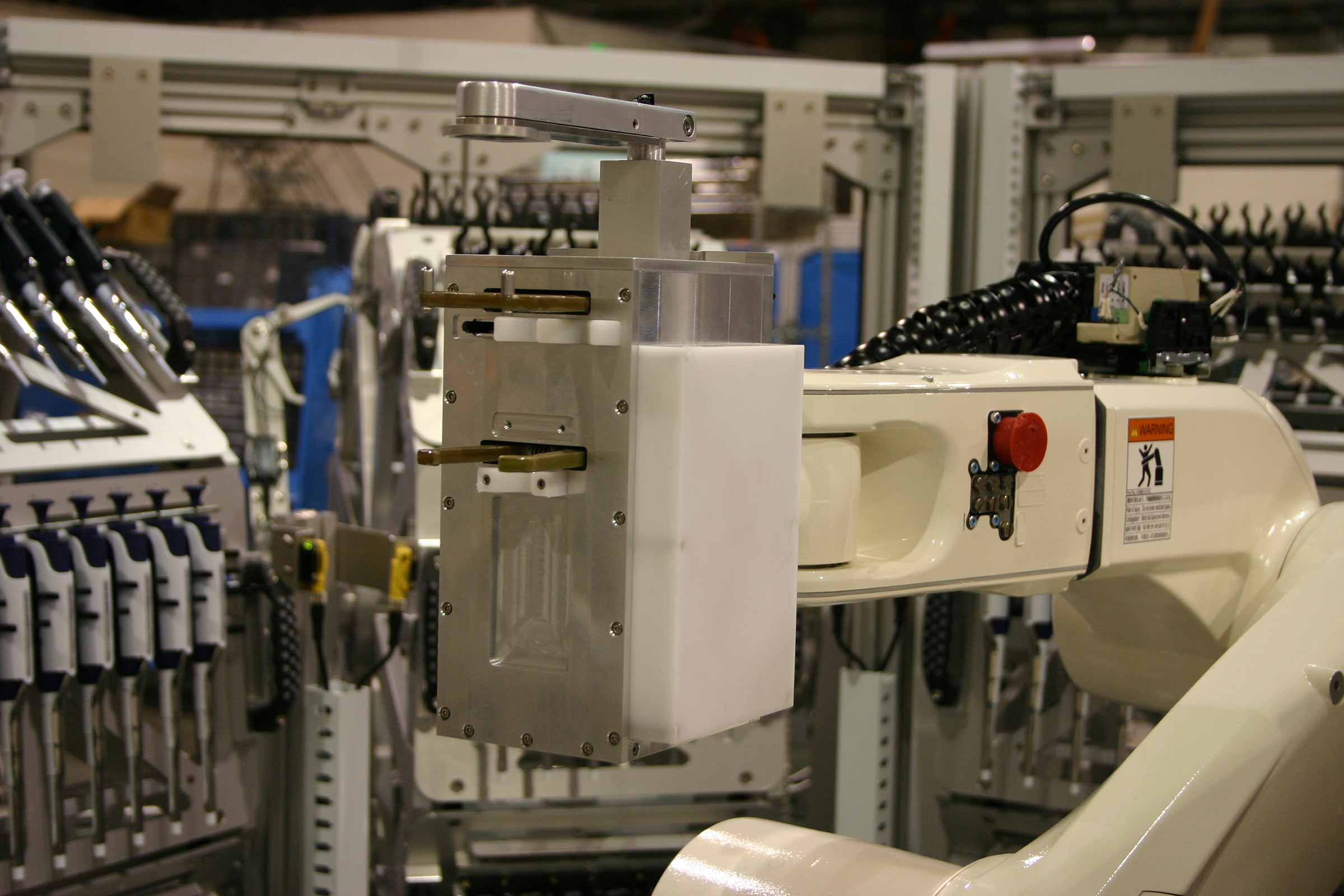

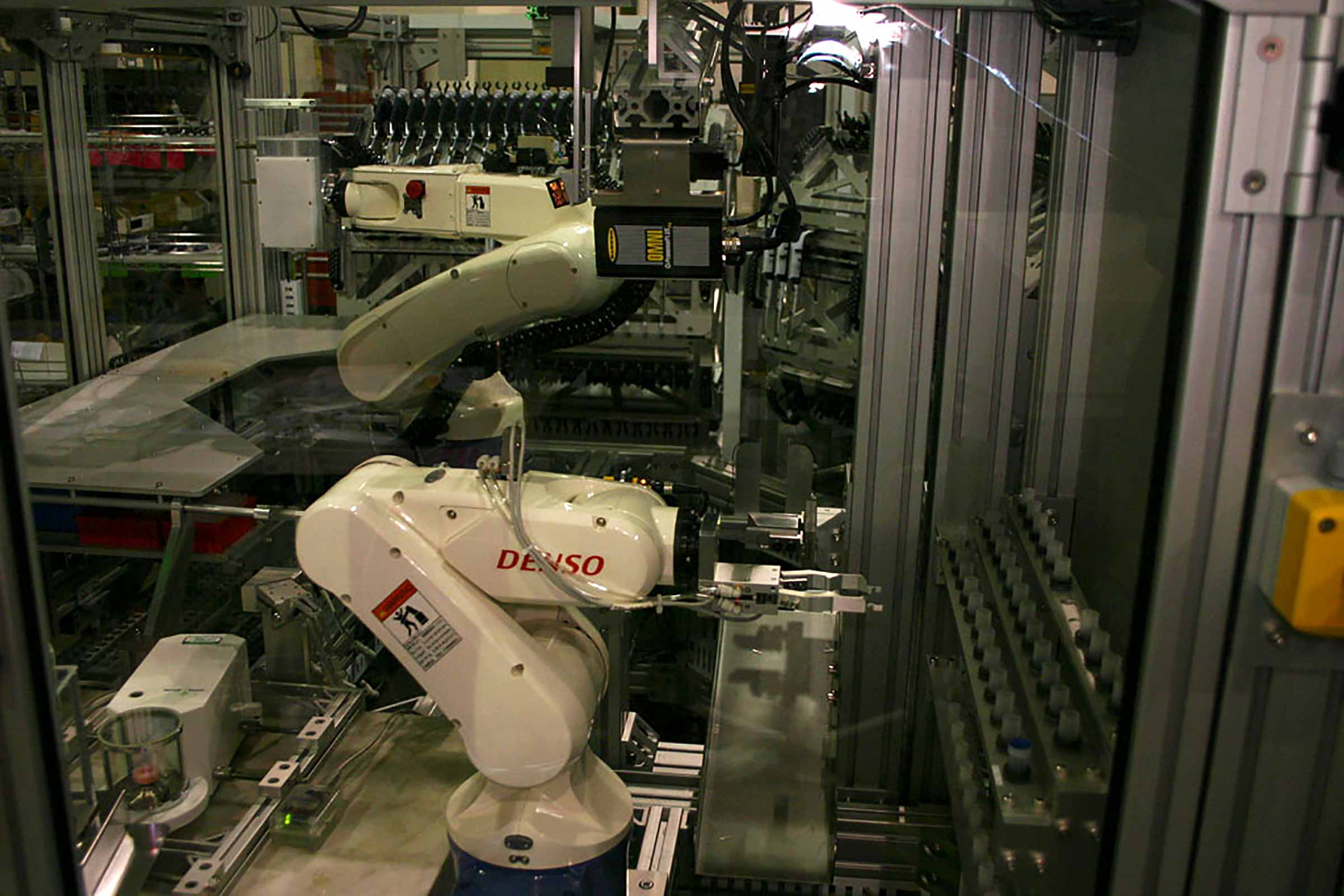

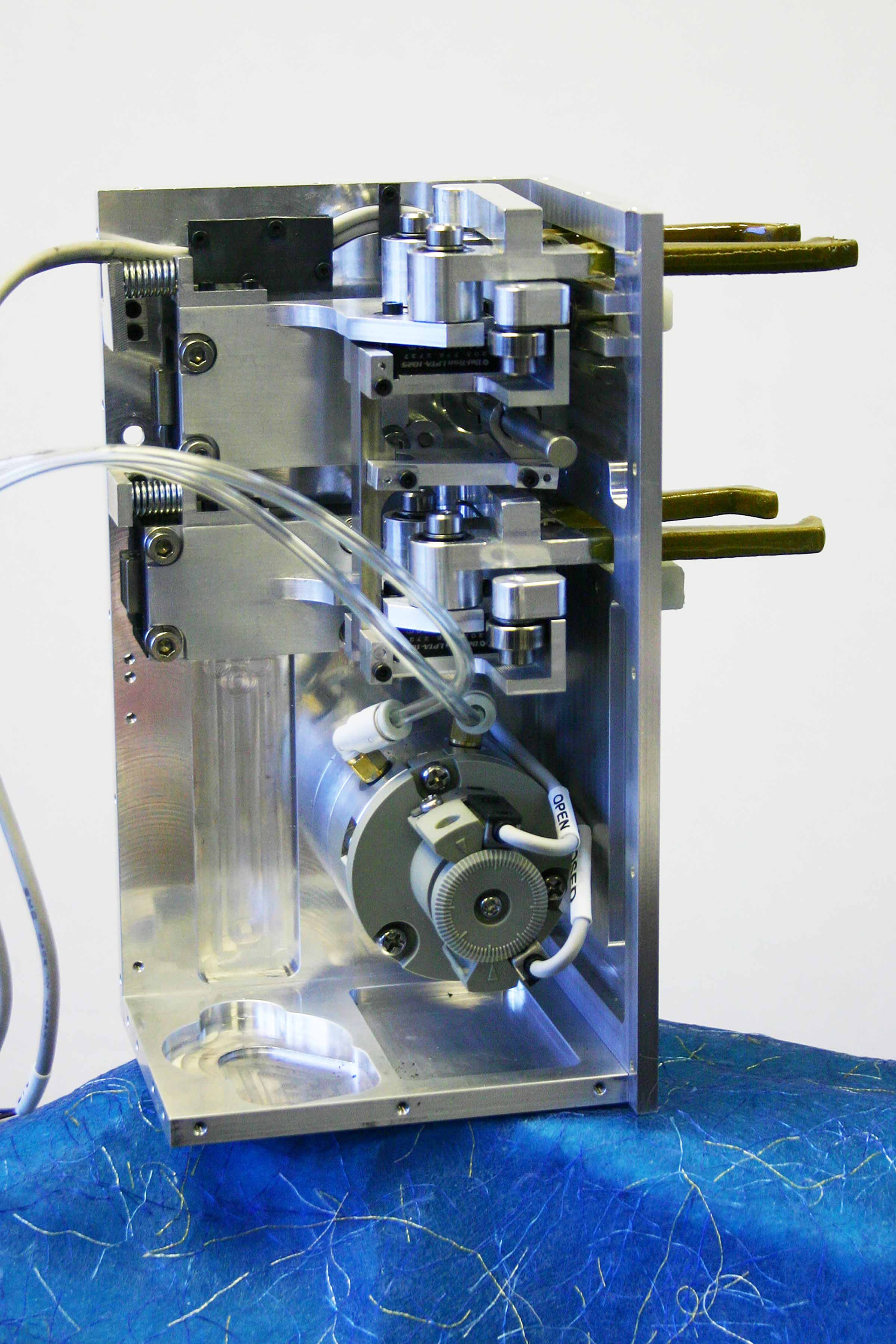

A special mechanical hand mounted on a high-speed six-axis robot, with force sensing and the ability to adapt to many sizes and shapes of handles, picks a pipette from a rack, installs a tip, adjusts the volume setting by reading the indicator dials and spinning a knob, draws a precise sample of fluid and drops it into a waiting vial. The vial is fetched, tared and presented by a smaller five-axis robot. After the fluid is dispensed, the pipette tip is touched off on the wall of the vial, then the vial is placed on the precision balance.

The system holds 160 pipettes to be tested, 160 that have been tested and passed, and up to 48 that have failed or need rework. Production Robotics has delivered three of these systems.